A Permit- To-Work is a formal written system used to control certain types of work that are potentially hazardous. A Permit- To-Work is a document which specifies the work to be done and the precautions to be taken. They allow work to start only after safe procedures have been defined and they provide a clear record that all foreseeable hazards have been considered.

A PTW is not simply permission to carry out a dangerous job. It is an essential part of a safe system of work which determines how that job can be carried out safely, and helps communicate this to those doing the job.

The PTW system should ensure that authorised and competent people have thought about foreseeable risks and that such risks are avoided by using precautions.

Why is Permit to Work (PTW) important in workplace?

· Identify the scope of a specific task

· Identify hazards and controls associated with the work tasks

· Identify the personnel who have oversight responsibility

· Identify the personnel performing the tasks

· Verify adequate control over the return to normal operations

· Assign responsibility for various tasks

· It promotes coordination

· It allows communication and awareness among the Site Management, Foremen/Supervisors and all personnel who carry out the operations

When Permit to Work (PTW) Necessary?

· Whenever required by risk assessment and/or PTW Project procedure.

· When an activity that requires to lower the safety mitigation measures normally in place is performed (usually during maintenance).

· Whenever it is required to manage simultaneous operations that might clash one with the other.

· Whenever work has to be performed that is NOT a routine operation.

· Whenever it is intended to carry out any work which may adversely affect the safety of personnel, the environment or the plant.

Types of Permit to Work (PTW)

PTW is mainly categorised into two main types namely:

1. Hot work permit

2. Cold work permit

1. Hot Work Permit

The following work activities require hot work permits:

· Cutting

· Electrical works

· Welding

· Burning and heating operations

· Use of portable gas or arc welding equipment

· Grinding

· Portable powered tools electrical/combustion engine

· Bunkering

2. Cold Work Permit

A cold work permit would be required for the following activities:

· Scaffold erection

· Lifting operations

· Installation of life-line and/or retractable anti fall system

· Working on MEWP (mobile elevated working platform)

· Temporary closure of site roads

· Painting or blasting operation

· Pressure testing (e.g. hydro testing; pneumatic test )

· Handling of the hazardous substances (e.g., toxic/corrosive chemicals, asbestos, etc.)

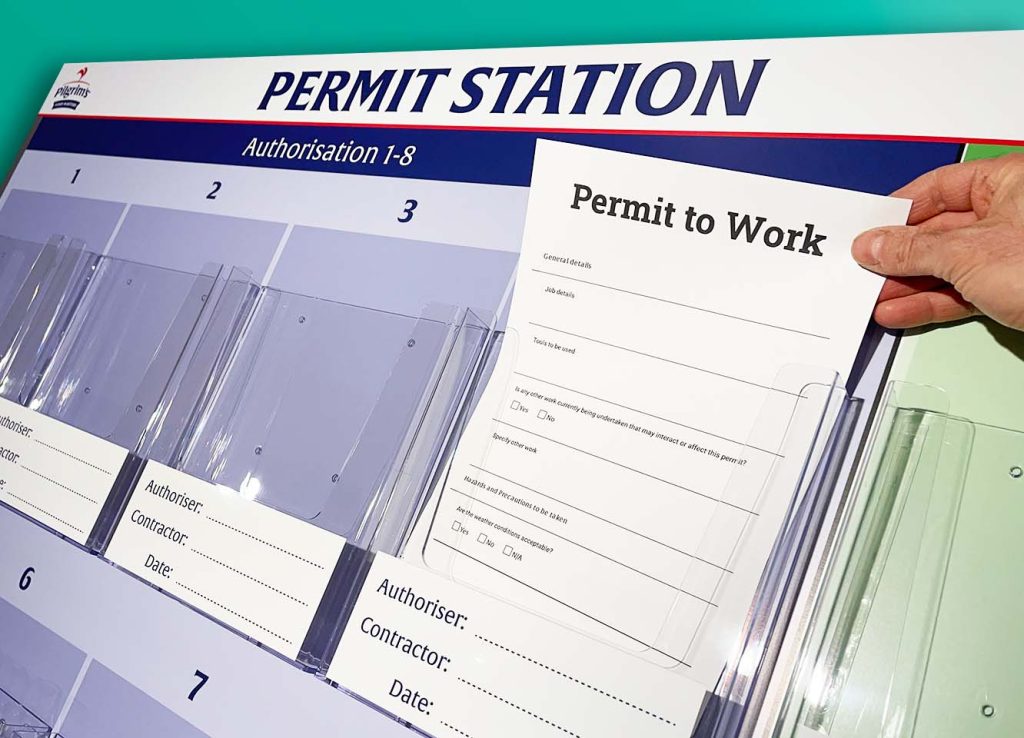

Contents of a Permit To Work System

The general details to be included in a PTW system can be summarised as follows:

1. Permit title

(Cold work, Hot work, etc.)

2. Permit reference number

reference to other permits or isolation certificates

3. Job location

4. Plant / equipment identification

5. Description of work to be done and its limitations

6. Hazard identification

including residual hazards and hazards associated with the work

7. Safety precautions (and actions in the event of an emergency)

people who carried out precautions, e.g. isolating authority, should sign that precautions have been taken

8. Protective equipment (including PPE) Requirements

9. Issue

signature (Permit authoriser) confirming that isolations have been made and precautions taken, except where these can only be taken during the work.

10. Acceptance

signature (task supervisor) confirming understanding of work to be done, hazards involved and precautions required. Also confirming permit information has been explained to all permit users.

11. Extension / shift handover procedures

signatures confirming checks made that site remains safe to be worked at, and new performing authorities and permit users made fully aware of hazards/precautions. New expiry time is given.

12. Hand-back

signed by Permit Authoriser and Task Supervisor certifying work completed and site is safe.

In conclusion, a PTW will not prevent incidents unless their need and use has been established, their requirements are strictly adhered to, appropriate equipment is available for testing and implementation and personnel are aware and competent.

Primelift Safety Resources Limited provides training of personnel in permit to work.

Visit our website at www.primeliftsafetyng.com. Call us on +234 9115687051 or Email us at training@primeliftsafetyng.com