Shackles are important and common lifting accessories used in various rigging and lifting operations. Shackle comprises of a body and pin which are readily separable and can be used to connect a load to a lifting appliances directly or in conjunction with other lifting accessories.

Shackles are produced by drop forging, which can be easily identified by the flash line around the body. They are normally forged from various grades of steel, the higher quality alloy steels giving, size for size, a higher safe working load than those made in higher tensile steels, and correspondingly higher tensile steel shackles have a higher safe working load than those made in mild steel.

Types of Shackles

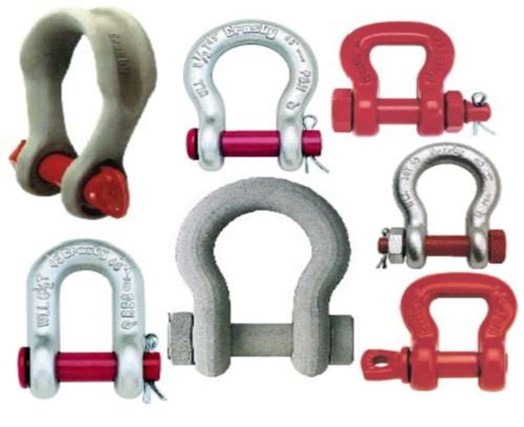

There are two types of shackles in use namely Bow Shackles and Dee Shackles.

Bow shackles are designed to enable three or more items to be joined. They are used for both vertical and angular lifts.

Dee shackles are generally used for joining two items in a straight line. They are only suitable for vertical lifts. The use of dee shackles is currently obsolete in most workplaces.

Shackle Pin Types

For Dee and bow type shackles there are essentially only two types of pin available: the screwed pin type and the nut and bolt type.

- The screwed pin is suitable for most purposes provided there is little risk of the pin becoming unscrewed during the lifting operation. It has the advantage of keeping the shackle as a quick-to-assemble, two component item.

- The nut and bolt pin, together with a split retaining pin, is a four component item. The advantage of the latter, however, is that the pin cannot unscrew in service. It is therefore more suitable in applications where there may be movement which could cause the shackle to unscrew; where it remains connected for extensive periods; or in situations that do not allow the shackle to be seen easily and checked for security.

Safe Use of Shackles

- Always inspect shackles before use and before placing them in storage.

- The correct shackle body and pin must be used and they must be of the same grade. Accidents have occurred where the user has put a mild steel pin in an alloy steel body or replaced a screw pin with a nut and bolt.

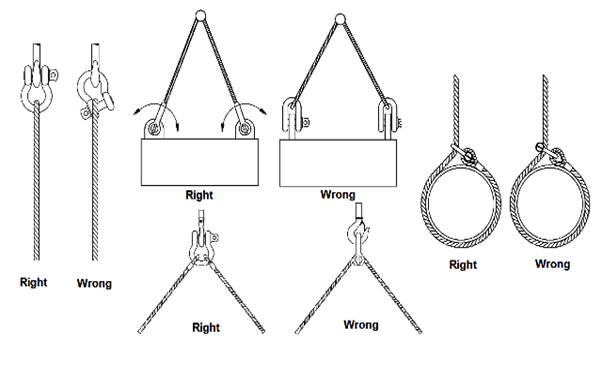

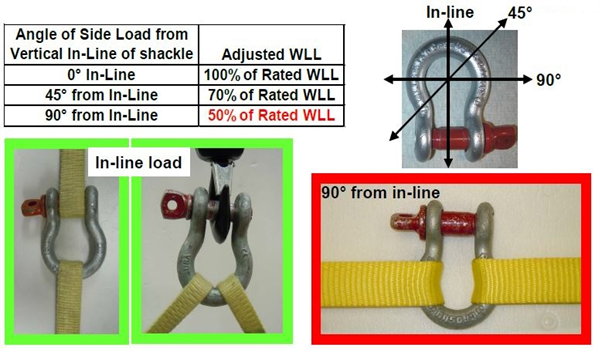

- The shackle must be compatible with all of the other fittings in the slinging arrangement, taking account of increased resultant loads due to angular loading, and it must seat correctly with mating parts.

- The pin must be correctly screwed into the shackle eye, i.e. finger tight, so that the collar of the pin is fully seated on the shackle eye.

- Shackles which have a positively locked pin, e.g. bolt, nut and split cotter pin, should be used for applications where the shackle cannot be observed or where the pin may unscrew when in service and, in the worst case, release the load.

- Never load shackles beyond their Working Load Limit.

- Remove any Shackle from service if WLL marking is not legible.

- Do not use a shackle outside the temperature range of – 20 °C to 200 °C.

- Shackles should not be immersed in acidic solutions or exposed to acid fumes or other chemicals.

- Shackles should not be modified, heat treated, galvanised or subject to any plating process without the approval of the manufacturer.

- When using shackles in conjunction with multi-leg slings, due consideration should be given to the effect of the angle between the legs of the sling. As the angle increases so does the load in the sling leg and consequently in any shackle attached to the leg.

- When removing shackles from the lifting setup, it is good practice to re-assemble the shackle immediately. Leaving the pins loose can damage the threads.

Correct and Incorrect Use of Shackles

Inspection of Shackles

The Lifting Operations & Lifting Equipment Regulations 1998 (LOLER) make it clear that all shackles used for lifting purposes are lifting accessories. They should therefore be subject to a thorough examination by a competent person at least every six months.

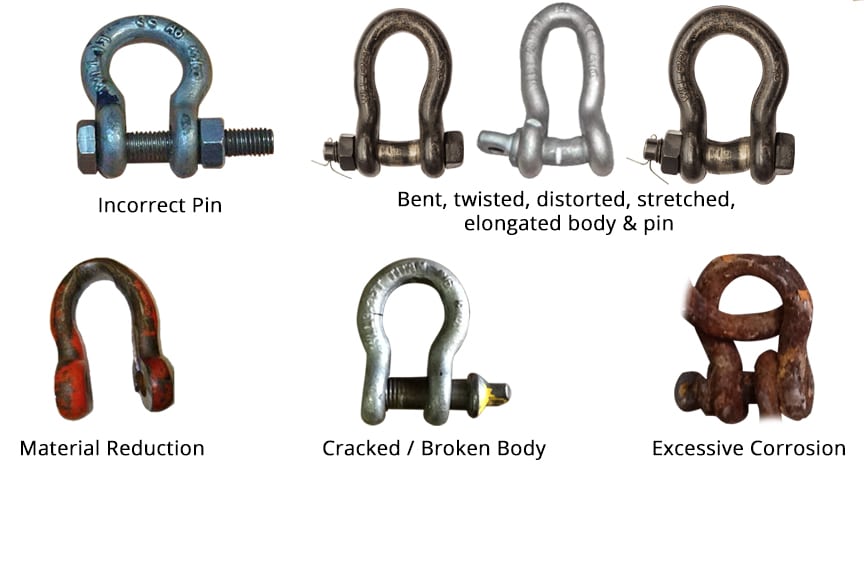

Shackles must be removed from service when any of the following items are found:

- Manufacturer’s name or trademark and/or WLL are missing or illegible.

- Weld splatter, arc strikes, or heat damage.

- Excessive corrosion.

- The shackle is bent, twisted, distorted, stretched, or cracked.

- Nicks or gouges.

- A 8% reduction of any part from original manufacturer specifications (excessive wear).

- Pin does not engage correctly.

- Damaged threads to the pin.

- Excessive jaw opening of the shackle body.

Shackles play a critical role in various rigging and lifting operations across a wide range of industries. Shackles require regular inspections and maintenance to ensure safe and efficient use. Using shackles without a thorough safety check before each use can be dangerous as you might face deadly accidents as a result.

Primelift Safety Resources Limited provides training on the safe use of lifting equipment. Contact us for more information. www.primeliftsafetyng.com. Call us on +234 9115687051 or Email us at training@primeliftsafetyng.com.