Wire rope slings are the most commonly used lifting accessories in major industries like, construction, oil and gas, marine and manufacturing. Wire rope slings are a prime component of all rigging and lifting activities.

Incorrect use of wire rope slings has resulted in many hazardous accidents in the workplace. Sling failures and incorrect rigging methods are one of the major reasons of these accidents. Common accidents that occur due to sling failure include imbalanced or loose loads slipping off the sling, or incorrect rigging causing the load to swing and rotate, which poses a danger to personnel standing near/under it.

Selecting Wire Rope Slings

When selecting a wire rope sling to give the best service, there are four characteristics to consider: strength, ability to withstand fatigue (e.g., to bend without distortion), ability to withstand abrasive wear, and ability to withstand abuse.

- Strength – Strength of wire rope sling is a function of its size (e.g., diameter of the rope), grade, and construction, and must be sufficient to accommodate the maximum applied load.

- Fatigue (Bending without Failure) – Fatigue failure of wire rope sling is caused by the development of small cracks during small radius bends. The best means for preventing fatigue failure of wire rope slings is to use blocking or padding to increase the bend radius.

- Abrasive Wear – The ability of wire rope sling to withstand abrasion is determined by the size and number of the individual wires used to make up the rope. Smaller wires bend more readily and offer greater flexibility, but are less able to withstand abrasion. Larger wires are less flexible, but withstand abrasion better.

- Abuse – Misuse or abuse of wire rope slings will result in their failure long before any other factor. Abuse can lead to serious structural damage, resulting in kinks or bird caging. (In bird caging, the wire rope strands are forcibly untwisted and become spread outwards.) To prevent injuries to workers and prolong the life of the sling, strictly adhered to safe and proper use of wire rope slings.

Safe Use of Wire Rope Slings

- The sling must not be used to lift a load that is in excess of the safe working load marked on the sling, taking account of the slinging mode.

- Inspect wire rope slings before use and before placing into storage.

- Use packing to prevent damage to the wire rope sling from corners or edges and to protect the load.

- Never drag wire rope slings over floors, etc., or attempt to drag a trapped sling from under a load.

- Never use wire rope slings in contact with chemicals or heat without the manufacturers’ approval.

- Where more than one wire rope sling is used to lift the load, each sling should be adequate for the share of the load imposed on it taking into account the slinging method.

- The upper terminal (master links) of the wire rope sling should be seated in the bowl of the crane hook, never on the point, nor wedged in the throat.

- The joining together of wire rope slings made from rope of different lay directions must never be considered since this may cause the ropes to un-lay, thus seriously affecting the capacity of the slings.

- Sling hooks of multi-leg wire rope slings should be positioned so that they face outward from the load, without inducing a twist in the rope.

- Never reposition wire rope slings by hammering, either to bring an out of balance load into balance or, in the case of choke hitch, to tighten the bight.

- Great care should be taken to avoid shock loading as it effectively increases the weight of a load and could result in the lifting equipment being grossly overloaded. In the case of wire rope sling, this can result in internal, and therefore unseen, damage.

In-Service Inspection of Wire Rope Slings

ln addition to the thorough examination necessary under statutory provisions, all wire rope slings should be visually inspected by a responsible person prior to use or on a regular basis, taking account of the conditions of service. This inspection must be carried out with the sling in a reasonable clean condition and in adequate lighting.

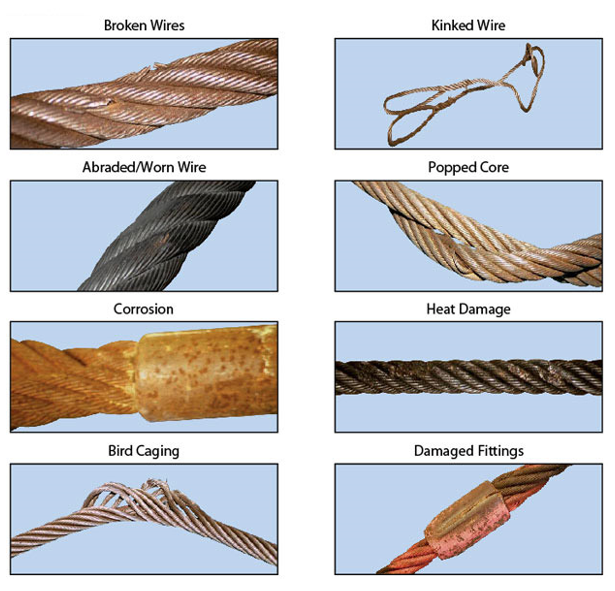

If any of the following faults are present, the sling should be withdrawn from service and referred to a Competent Person:

(1) Illegible markings, i.e., the sling identification mark and the safe working load.

(2) Damage or wear to any of the terminal fittings including protective thimbles.

(3) Mechanical damage to the rope, fittings, hand splice (if any) or the ferrules, including indication of cracking or slippage.

(4) Broken wires. If three or more broken wires are detected in a very short length, wire rope sling should be removed from use.

(5) lneffective safety latches on hooks.

(6) Corrosion or drying out of lubricant.

(7) Kinks or other permanent set in the wire rope sling

(8) Disturbance to the position of wires in the strands or strands in the rope or protrusion of core.

(9) Evidence of heat damage, e.g, melted lubricant, blueing of wires, contamination by weld splatter, evidence of arcing etc.

(10) Opening out of hooks, i.e, noticeable increase in the throat opening, or any other for distortion in the terminal fittings, including thimbles.

Wire Rope Slings Damage Examples

If wire rope slings are found to be defective, they should be immediately remove from service.

Damaged or defective wire rope slings should be destroyed to eliminate re –use.

Primelift Safety Resources Limited provides training on the safe use of lifting equipment. Contact us for more information. www.primeliftsafetyng.com. Call us on +234 905687051 or Email us at training@primeliftsafetyng.com